Product description

The color coated roofing sheet is made of color-coated steel coil and processed by a Roll Forming Machine.

The main material of color paint coating is PE paint, which has the characteristics of low price, various colors and high-temperature resistance.

The corrugated colour coated sheets coating is a product obtained by subjecting a cold rolled steel sheet or a galvanized steel sheet to a surface chemical treatment (roll coating) or a composite organic coating (such as a PVC coating) and then baking and curing.

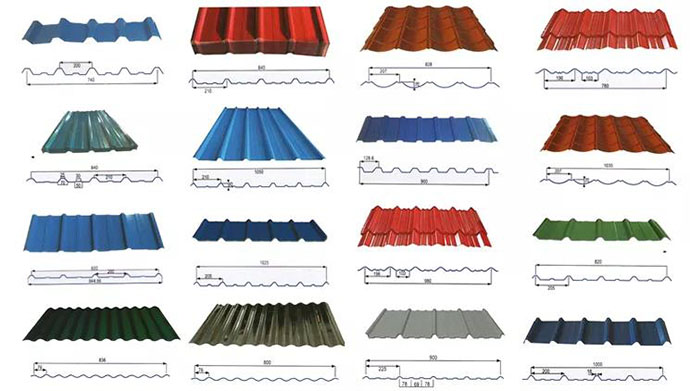

Its base steel is cold rolled sheets, hot galvanized steel sheets, and aluzinc steel sheets. The coating types can be classified into polyester, silicon modified polyester, polyvinylidene fluoride, and plastisol. The surface state of the color coated sheets can be divided into a corrugated coated sheet, a corrugated embossed sheet, and a corrugated pattern sheet.

The color coated sheets for construction are generally made of hot-dip galvanized steel sheets and hot-dip aluzinc steel sheets. They are mainly processed into corrugated sheets or sandwich sheets with polyurethane and are used for the construction of industrial and commercial buildings such as steel structure workshops, warehouses, and freezers. Roof, wall, door.

For PPGI corrugated steel roofing with a service life of 25 years and above, polyvinylidene fluoride (fluorocarbon PVDF) should be used for the paints type.

For pre-painted corrugated steel roofing with a service life of 15 years or more, the paints type should use silicon modified polyester or high weather resistant polyester.

For color corrugated steel roofing or temporary roofs with a service life of 10 years or more, polyester is used for the paints type.

Quality Inspection

Products show

Contact us

Sales:Queency

Phone Number: 86 18920479159

E-mail: topsales@pbsteelgroup.com

Whatsapp No.:86 18920479159

.jpg)